Bandsaw Blade Terminology

- Cutting speed - The speed of the blade cutting the workpiece. It is usually measured in in meter per minute.

- Standard cutting speed - A list with recommended cutting speeds for various metals, based on a workpiece with a width of 100 mm.

- Frame feeding - Travelled distance of the saw frame without cutting in mm per minute

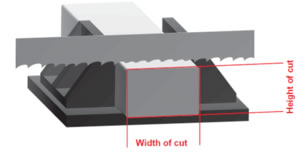

- Width of cut - The total distance the tooth travelling across the workpiece. It is measured from the point where a tooth penetrates into the workpiece to the end point

- Height of cut - The distance the saw blade travels from the penetration point to the leaving point.

- Cutting capacity - The amount of material machined in a specific time period, measured in cm² per minute

- Depth of cut - The distance that every tooth will penetrate into the material during one cutting stroke

- Feed - The average speed of the saw frame during cutting (mm per minute)

Cutting speed

Speed of the blade cutting through the surface of the workpiece material is it’s cutting speed.Higher is the cutting speed , the larger will be the cutting angle and the more effective will be the cutting process.

Speed of the blade cutting through the surface of the workpiece material is it’s cutting speed.Higher is the cutting speed , the larger will be the cutting angle and the more effective will be the cutting process.

The cutting speed is restricted by the machinability of the material and by the heat generated during cutting process.If the cutting speed is too high or if very hard metals are to be cut, excessive heat is generated. This causes a reduction in the life of the band saw.

Effect of speed seen on chips is as follows

- Optimum feed – rolled , silver chips

- Low Feed - thin or powdery chips

- High Feed –burnt, heavy chips

Factors which influence Band saw life are:

- The number of teeth of the bandsaw.

- The type of teeth.

- Teeth per Inch of bandsaw(TPI).

- The machine operator.

- The tension of the bandsaw.

- The cutting speed.

- The feed force.

- The quality of the bandsaw.

We offer our customers with premium quality Bimetal Band saw Blades which are used for cutting ferrous and non ferrous materials. High profile engineers is one of the biggest distributors of bi-metallic bandsaw blades .These are durable and provide high efficiency in work. Some of the salient features are :-

- High performance

- Extremely long service life

- Helps in reducing the cutting time

Our experience in the sawing field of over twenty years has established High Profile Engineers to be one of the renowned distributors for bi-metallic band saws.

High profile Engineers will offer the best quality products available. We do offer you a quality guarantee as we are authorized agents for bi-metallic bandsaw blades. We stand behind our product, and will replace any band saw blade that has failed at the weld prematurely.

Pitch

The teething is indicated in TPI(Teeth per inch)

Following table will guide you in selecting right TPI for solids.

| TPI selection table | ||

|---|---|---|

| Constant Pitch | Thickness (mm) | Variable Pitch |

| 18 | 2 3 |

10/14 |

| 14 | 5 8 |

8/12 |

| 10 | 12 16 |

6/10 |

| 8 | 22 30 |

5/8 |

| 6 | 40 70 |

4/6 |

| 4 | 100 140 |

¾ |

| 3 | 200 240 |

2/3 |

| 2 | 300 4450 |

½ |

| 1.2 | 600 | 0.75/1,2 |

| 0.75 | + | |